Adhesive Peel Tester distributing|adhesive tester equipment : companies ASTM D903-98 is a common tensile test used to evaluate the Peel-Stripping Strength of Adhesive Bonds. Back; Home; Products. Materials Testing. Universal Testing Systems. Automated Testing Systems. . To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a .

webConheça o BSF App. Tecnologia a serviço dos nossos beneficiários! Aplicativo mobile. Saiba mais sobre o “Tá na Hora”. E não esqueça mais o seu medicamento! Tá na hora! .

{plog:ftitle_list}

Resultado da 28/10/2020. IMAGENS CHOCANTES! Motorista tenta parar caminhão sem freio e é esmagado por roda. TUDO FILMADO. VEJA VÍDEO. Foto: .

Labthink offers motorized peel testers in several different peel configurations from a wide range of force gauges, test stands, grips, and accessories. Labthink peel testers help you save on time, money and wastage by ensuring your .Adhesive Peel Tester is a Tensile Tester specifically designed to perform the following : 180° Adhesive Peel Test. 90° Adhesive Peel Test. Loop Tack Test. Roll Peel Test. Release Force Test of Silicon Liners; Suitable for : PSA Tapes and Labels. Confirms to : PSTC 101 / PSTC 16 / PSTC 8 / ASTM D 3330 A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A . Peeling takes a wide array of forms. In the most basic sense, a peel test can consist of (1) a laminate comprising of two (or more) layers peeled apart, often at the interface or (2) an adhesively bonded joint in which two substrates are joined by an adhesive layer and then peeled apart, or (3) peeling of a single, adhesive material from a substrate or itself.

Peel strength is generally used to measure the bond strength of a material, typically an adhesive. Peel strength is the average load per unit width of bond line required to separate bonded materials where the angle of separation is 180 degrees.ASTM D903-98 is a common tensile test used to evaluate the Peel-Stripping Strength of Adhesive Bonds. Back; Home; Products. Materials Testing. Universal Testing Systems. Automated Testing Systems. . To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a .

Adhesive Peel Strength Tester . Labthink offers motorized peel testers in several different peel configurations from a wide range of force gauges, test stands, grips, and accessories. . its international headquarters is in Boston, USA. Labthink has more than 50 international distributors and more than 30 international service providers .

Various methods of adhesion testing include pull-off testing, peel testing, shear testing, and cross-cut testing. How do you increase adhesion strength? Adhesion strength can be improved by proper surface preparation (such as cleaning, roughening, or applying a primer), optimizing the adhesive formulation, or modifying the curing process.According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups1. Test frame - produces the force necessary for the test.. 2. Control panel - used to create and run tests, manage results, create reports, and manually control the test frame.. 3. Force sensor - series FS05 and R07 force sensors measure both tension and compression force. They mount directly to Series F test frames. 4. Grips and fixtures - many types of grips are available.

Tensile Strength Tester. (Adhesive Peel Tester) Single Column Design Fully Automatic Computerised Model (with Windows 7 based PC software). . Distributor PackTest Indonesia by PT Unitek Solusi Indonesia. Bizlink Citra Raya Blok P.03 No.106, Jl.Pemda Tigaraksa Sukamulya Cikupa Tangerang, Banten 15710, IndonesiaASTM D3330-- Standard Test Method for Peel Adhesion of Pressure Sensitive Tape ; ASTM D3654-- Standard Test Methods for Shear . its international headquarters is in Boston, USA. Labthink has more than 50 international distributors and more than 30 international service providers. Contact Info America; Europe .ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests . The ADT is a new tool for measuring adhesion durability using a simple peel-test specimen that fills an unmet need for a fast adhesion measurement ideally suited for durability studies. The combination of constant applied load and environmental stress while measuring the crack speed is ideal for generating failure-rate equations for adhesive .

There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main .

The Peel Adhesion Tester - UniTest is highly configurable tester designed to perform wide range of tests including peel adhesion test. The tester can conduct 90 degree, 180 degree and loop tack peel adhesion tests.You might find yourself in the face of an unknown material or coating. Today we’ll show you why and how to perform a successful (and unsuccessful) adhesive peel test when using Ritetack Construction Adhesive.. In this video, we have . To ensure quality, manufacturers of products like tape, labels, and wallpaper rely on adhesion testing. Without proper bonding between materials, it is possible for products to peel away or fail prematurely, which could compromise the manufacturer’s reputation as well as market share.. John Bogart, managing director of Kett US, explained, “To create products that require .The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.

C620H Friction / Peel Tester is used for testing the coefficient of friction and peel strength of plastic film, paper, packaging materials and more. . CZY-8SA Lasting Adhesive Tester can be used to test the holding power of pressure-sensitive tapes, pressure-sensitive labels and protective films, etc. . Labthink is in Jinan, China; its .Adhesive Technical Services. Independent laboratory testing and consultancy for adhesives, tapes and labels. Full range of laboratory testing equipment for adhesives, including peel adhesion, tack, shear and release testers. Agents for ChemInstruments. 180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle.Stud pull coating adhesion testing, for instance, is a very common test used in micro-electronic coatings or other forms of "thin film" application on rigid substrates. Typical graph showing a test performed on adhesives, paints or varnishes: Typical test measurements include: - 180 degree and 90 degree peel tests

Peel adhesion testing is measuring the force required to remove a tape specimen from a test panel at a controlled angle (usually 180°or 90°), at standard rate, and with a defined dwell time. The tape is applied using a weighted rubber roller to a stainless steel (or other panel material that is defined) and then allowed to dwell on that panel.ISO 8510-2 Adhesives—Peel Test for a Flexible-bonded-to-rigid Test Specimen Assembly—Part 2: 180 degree peel FINAT FTM-1 180 peel adhesion at 300 mm per minute (from application substrate) . or your authorised distributor if any items are .

Adhesion testing equipment is used to measure the force required to separate two surfaces. This type of testing is often used in the manufacturing and construction industries to determine the strength of adhesives. There are a variety of adhesion testers on the market, but all operate by applying a known force to a sample and measuring the .

Testing Equipment for Peel Adhesion. A multi-functional peel tester is used to evaluate the peel force in different peel angles, rates, and temperatures (Figure 1). The peel tester is capable of evaluating independent parameters of peel rate from 15-300 cm/min, angle from 0° to 180°, and temperature (by a

polarimeter cuvettes

peel testing machine

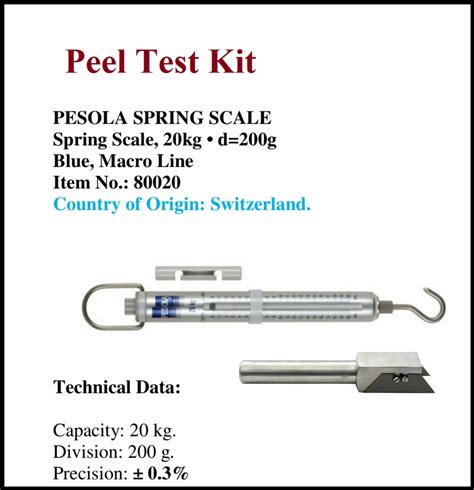

peel testing kit

Resultado da 3 dias atrás · IPTV playlist in M3U format with 📺 TV channels and 📻 radio stations in 🇵🇹 Portuguese. Public and official streams only.

Adhesive Peel Tester distributing|adhesive tester equipment